Our wide range of Products and Services are ...............

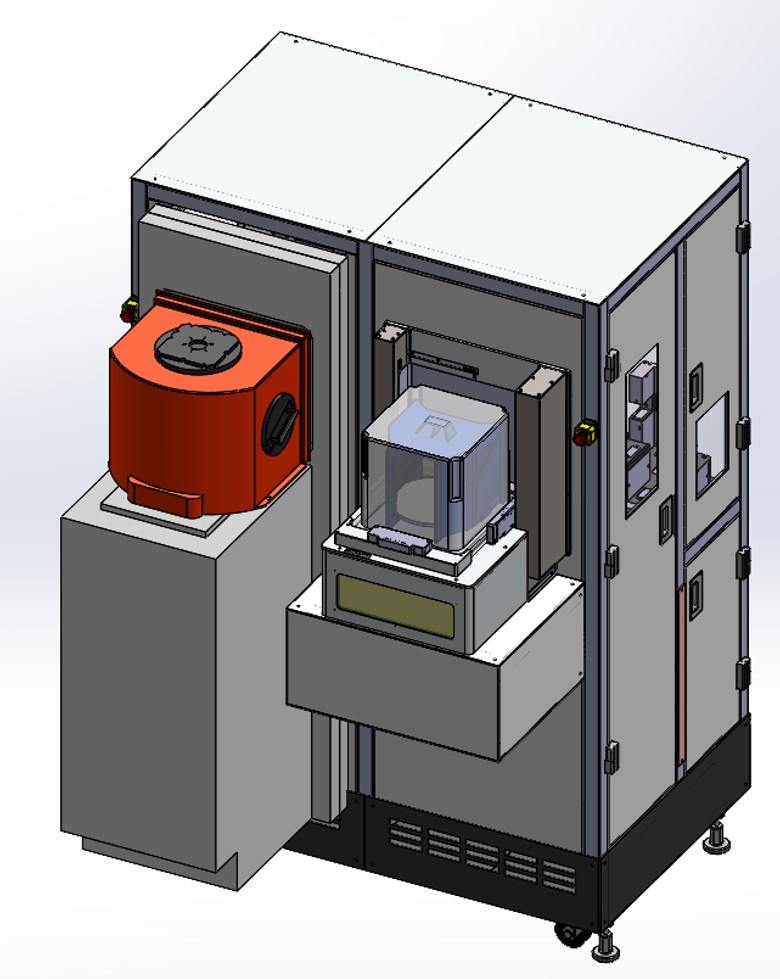

Equipment Front End Module (EFEM)

- 300mm or 200mm load port configurable

- Atmospheric Clean Robot

- Pre aligner available

- FFU Controller

- Covers -> Standard Carbon steel with powder coating

- Service Door -> Al & Carbon steel with powder coating

- RFID / Barcode reader

- OCR (Optional)

- SECS/GEM (Optional)

- E84 Signal (Optional)

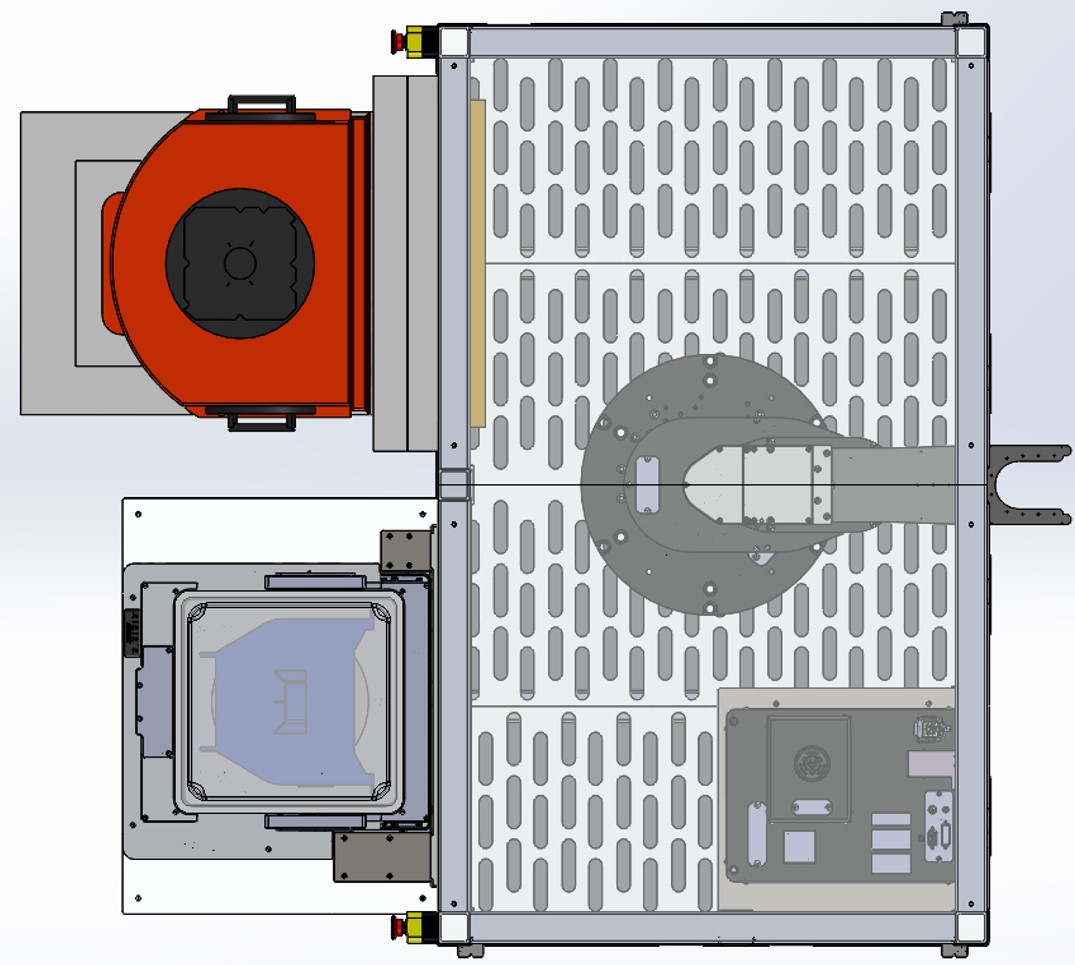

NexZM@

- 0.1 to 3mm Thickness Measurement

- 0.1 to 12 mm Wapage Measurement

- Repeatability : 5um

- Precision +/- 4.4 um

- Accuracy : +/- 4.4um

- Optional : Manual/ Auto Load/Unload

- SECS/GEM Enable

CDM (Chemical Dispense Module)

The system start from Raw Slurry Supply with mixing of DI water and Slurry by Weight machine, after mixing it transfer to Day-tank which Re-circulate in the loop.

Conditioning Monitoring (Predictive Sudden Failure)

Continuously monitor machine health, run time, and detect unexpected machine failures such as early bearing failure, unbalance, misalignment.

Robot And Controller Repair, Refurbish

Wet and Dry , Inverted and Non-Inverted Robot Repair, Service and Test.

Robot And Controller Repair, Refurbish

Wet and Dry , Inverted and Non-Inverted Robot Repair, Service and Test.

DI Water Booster Pump

Booster pump is to increase incoming fluid pressure when there has limitation on facility support pressure. It design with PLC control with alarm monitoring on pressure.

Slurry Or Chemical Mixing & Blending System

Customised Slurry and Chemical Mixing, Blending System. It support 50L to 100L mixing capacity with user desired Chemical, Slurry, H2O2 ratio.

Local Chemical and Slurry Supply and Control System

To supply local chemical or slurry with demand flow of 100 ml/min to 400ml/min. It is useful on places where there is difficult to access global chemical supplying system. With local supplying system, end user can just be able to hook up any chemical with desired demand flow to the system.

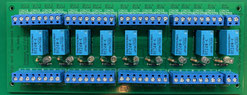

Design and Fabricate Customized PCB

Using Eagle software to design and fabricate customized PCB layout and schematic diagram. Reverse Engineering for obsolete parts. Customized control PCB for interfacing IO cards.

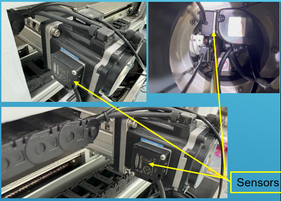

Material parts drop detection system

Special cutting edge design to monitor dropping of parts that attach in the system. It consist of customized holder with sensor that can able to differentiate with or without parts during processing

Customized PM Trolley

Design and Build Customized PM trolley for Fab user. It made with Stainless Steel or PP material based on customer requirement. It also made customized slot for PM tool.

De-condition of CMP Equipment machine

Decon Used equipments. Vacuum, Seal and Woodcraft and keep in Air Con Warehouse Before Delivery to customer. (2017-2019)

Customised Single Slurry Manifold

Special cutting edge design to reverse Engineering to replace existing OEM slurry manifold.

Part No : AI-190001

Digital Pump Controller

Customize controller for diaphragm PUMP with using adjustable pump stroke. It provides steady pumping rate ranging from 5 l/min to 15 l/min.

Customised Leakage Detection System

To monitor liquid or slurry leakage system in Applied Material Reflexion LK tools. It connect with external buzzer, hence during fault leakage the system would not stop and wafers are save.

Customised Tool trip/hang Monitoring System

To alert Equipment Personal when tool trip or hang due to system components shorted. Tool will be able to recover in time and prevent wafers for scrapping

Slurry Switching Control and Manifold System

Special design for easy switching over 2 slurry system without hazarding for technician. It consist of special design PCB board to switch between 2 slurry distribution system.

Column & Booms System

Column & Booms are designed for economy, flexibility, ease of control, safe and precision operation. It consists of a base unit and vertical column which allows 359 degree rotation around the vertical axis, and a saddle that moves up and down the vertical column and carries a motorize boom that move in and out horizontally. With the optional travel car, the Column and Booms can move along the rail and perform welding function at various function

Convention turning rollers

Turning rollers are widely used to facilitate the welding and assembly of pipes, tanks, drums and pressure vessels of all types. In steel plate fabrication, turning rollers are now a standard production equipment to increase productivity in the welding and fabrication of cylindrical work pieces. With the use of turning rollers, high quality weld can be achieved, and manual handling can be minimized for both automatic and manual welding process

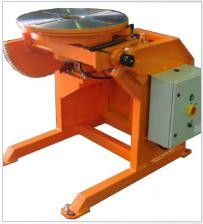

Welding positioner

Welding positioner offers an alternative economical solution for welding needs. All positioners are finely structured and machined to achieve performance with highly accuracy, ease of operation and flexibility

Electrode ovens

Industrial electrode ovens are designed for a variety of usages. They can be used in small and medium size weld shops to dry and store electrodes. Electrode ovens can also electrodes up to 700-mm length. They can also be used in high volume electrode baking at maximum temperature of up to 430 degrees Celsius. The electrodes are keep dry (free from moisture) at all times when kept in the ovens, this prevents impurities exiting from the weld bead.

Flux ovens

Flux ovens are designed for drying and dry storage of welding powder. It can store up to 200 litres of welding powder. The ovens are thermostatically controlled with a temperature range from 50 to 300 degrees Celsius.

Automatic SAW tractor

MZ series automatic SAW tractor has been designed to bear the serious condition that may be found in heavy structure works, shipbuilding and vessel manufacture etc. It is self-propelled mechanized wire feeder for submerged arc welding. The unit has proven invaluable in heavy fabrication industries because of its speed and ease of use.

Other Services

Apart from those products above. We also provide the following services and more..

- PCBA design and manufacturing

- Design and Fabricate compact switch gear and electronic control system

- Supply Air and electronics Pneumatic Parts

- Factory Automation system

Applied Instruments Pte Ltd

Applied Instruments Pte Ltd